|

|

|

|

|

Expand the range of printing orders to unprecedented levels with the industry’s top-class range of media handling. Create more business opportunities for print providers by handling a wide range of applications essential for digital printing.

Flexibility to deliver with speed

Quick turnaround

High productivity at 71 pages per minute

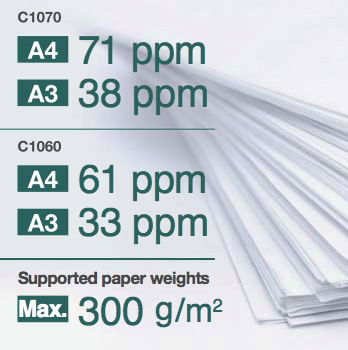

At 71 ppm* for the C1070 and 61 ppm* for the C1060 in both colour and monochrome, the C1070 series boosts productivity to meet large orders with ease. And with 38 ppm*2 productivity for A3 size outputs, booklets and imposition data can also be processed right away.

*1 A4 crosswise using 62 to 176 g/m2 paper.

*2 Using 62 to 176 g/m2 paper for C1070.

Enhanced thick paper productivity

Equal speed productivity for 62 to 176 g/m2 paper

Productivity is now even more efficient, whether using normal paper or coated, and for simplex or duplex printing, thanks to the improved fusing unit and process control. The C1070 series maintains high-speed outputs of 71 ppm* for paper up to 176 g/m2, boosting productivity even for mixed media.300 g/m2 boosting productivity even for mixed media.

A4 crosswise for C1070. 61 ppm for C1060.

High capacity plus high efficiency paper feeding maximise uptime

Max. 7,500-sheet paper feeding capacity

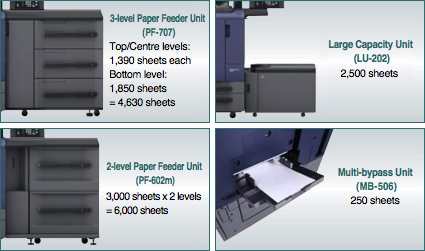

In addition to the 1,500-sheet capacity main unit trays, three types of paper feeding units are available for a maximum capacity of 7,500 sheets. Paper can be replenished on the fly to minimise downtime and maximise productivity regardless of the printing volume. A Multi-bypass Unit (MB-506) is also available for manual paper feeding.

From thin to thick, coated and more –media handling that empowers your business

Stabilised paper conveyance

Air suction belt paper feed system (PF-707)*

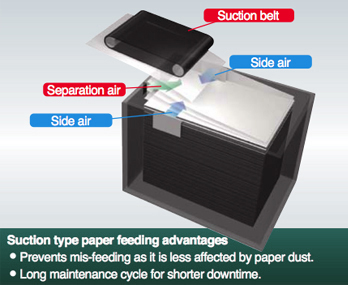

The newly developed Suction Feeder PF-707, which was previously only supported for mid-production models, is now available for the bizhub PRESS C1070 series. The air assist function blows air from the sides and front to raise each sheet of paper to stick on the suction belt for conveyance, realising stable and damage-free paper feeding, even for thick and coated sheets.* Optional

Reliable thin paper conveyance

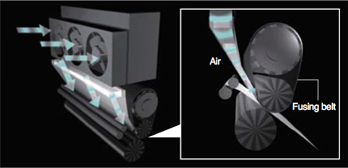

Air blow fusing separation mechanism

Air is blown to the area around the fusing nip to prevent the paper from winding around the roller. This also increases conveyance performance, greatly enhancing separation performance for thin sheets of paper. Air volume can be set automatically or manually according to paper type.

Cover the entire page

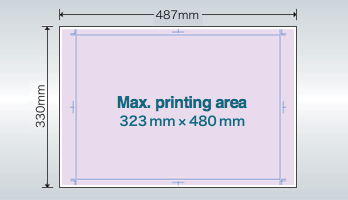

A3 full-bleed printing

The main unit’s Tray 2 and all optional trays can accommodate custom sized paper up to 330 x 487 mm for a maximum printing area of 323 × 480 mm, allowing full-bleed A3-size printing with registration marks, as well as A4 size imposition printing with registration marks.

Eliminate paper curls and static

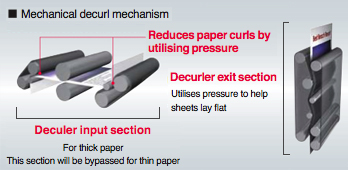

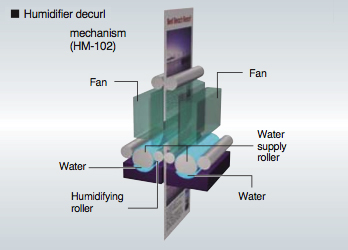

Hybrid decurler*

Create a hybrid curl correction system to prevent paper curls by combining the Relay Unit (RU-509), which employs a mechanical decurler, with the optional Humidifier Kit (HM-102). Paper curls can be optimally removed according to paper type, such as the mechanical decurler for coated sheets and the humidifying curler for non-coated sheets. The decurl amount can be adjusted manually, and responds flexibly to the changes in conditions.

* Optional

Mechanical decurler

Standard equipped Relay Unit (RU-509) employs a zigzag paper passage that reduces paper curls. Decurling strength can be adjusted in five steps for the optimal curl removal for thin paper to cardstock.

Humidifier type decurler*

In addition to removing curls using humidification for uncoated paper, HM-102 controls paper absorption by removing heat and minimising static electricity.

Create new business with postcard printing

Postcard printing*

Install the required options for high-volume postcard-size printing including direct mailings and invitations. Use with variable printing to create new business opportunities.

* With optional Paper Feeder Unit (PF-707/PF-602m) or Multi-bypass Unit (MB-506) installed.

For high-on-demand envelope printing

Envelope printing*

Expand your business opportunities by taking on new orders. The Envelope Fuser Unit (EF-103) supports printing for 100 × 148 mm to 248 × 375 mm envelopes. The optimally designed fusing roller almost eliminates wrinkles and ruffling, and the suction type paper feeder unit ensures pickup and conveyance from start to finish.

* Supported with optional Paper Feeder Unit (PF-707).

* Envelope Fusing Unit must be installed by the customer. Please contact your local Konica Minolta service provider for information regarding applicable envelope types.