Meet tight deadlines with greater productivity

High-speed printing for short runs and quick turnarounds

• Significantly faster RIP speed with new CPU and optimised data processing

• Tandem output*: Max. 250 ppm (A4 horizontal)

* Optional

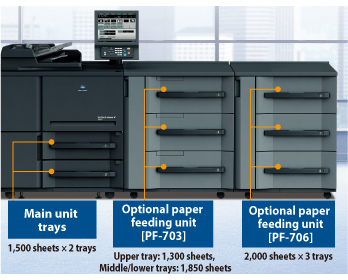

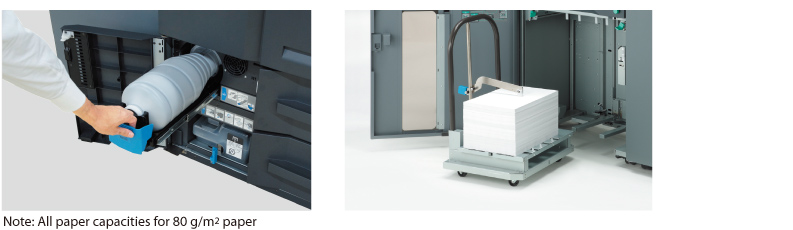

High paper capacity and on-the-fly consumable replacements

• Max. paper capacity: 14,000 sheets with the large capacity paper feeding units*. Auto-tray switch function keeps operations going without missing a beat.

• High-capacity toner can be replaced on the fly.

• Large-capacity stacker* with cart holds up to 10,000 sheets (with 2 stackers in tandem).

* Optional

Create more business with greater paper handling

Greater thin and thick paper support

* Thick paper support available only for optional Paper Feed Unit PF-703 and Paper Feed Unit PF-706 middle trays.

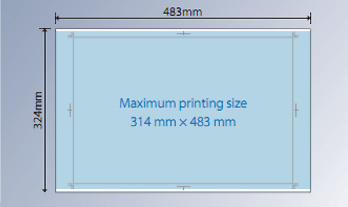

Full A3 outputs including crop marks

* PF-703 required

Envelope printing

* Paper other than envelopes cannot be fed when using the envelope fuser unit.Note: Please consult your service engineer for details regarding recommended paper,and envelope types and sizes.

Oher functions

• Register up to 256 types of paper with the Paper List (proile)

• Coated paper & embossed paper support

Error-free operation from start to finish

Air suction paper feeding system

* Optional

Multi-feed detection sensor

Paper skew sensor

This sensor detects paper skews to prevent misaligned printing.

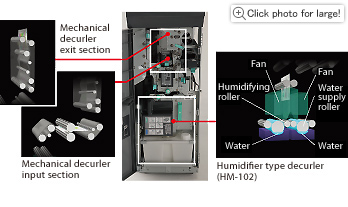

Hybrid decurling system*

* Optional

Versatility to meet more orders

Versatility to meet more orders

From hole punching, folding, corner and centre stapling to perfect binding, high-performance, high-productivity inline finishers allow the bizhub PRESS 1250/1052 to be optimally expanded to handle an abundance of orders.

| • Finisher FS-532 Compact all-in-one finisher • Folding Unit FD-503 6-way fold, Hole punch • Perfect Binder PB-503 Perfect binding • Saddle Stitcher SD-506 Saddle-stitched booklets / Three-fold • Large Capacity Stacker LS-505 • PI-PFU Unit FA-501 Large capacity cover sheet feeder when installed to PF-703 |

• Multi Punch GP-501* • Auto Ring Binder GP-502* • Relay Unit RU-509 Relay unit with mechanical decurler • Relay Unit RU-510 Relay unit with 2-ply reversal Notes: Required for bizhub PRESS 1250. Required for bizhub PRESS 1052 when equipped with PI-PFU –large-capacity cover sheet feeder that equips FA-501 to PF-703. |

Impressive image quality like never before

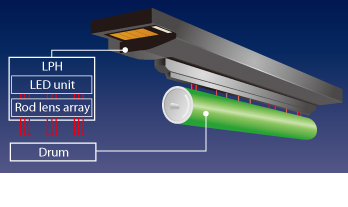

LED Print Head for 1,200 dpi high resolution outputs

Screen settings

Pre-setting screens (2 types of resolution in 3 patterns each) and dot screens are provided to maintain high resolution. High quality print images are provided by using the optimal screen to match the output.

| Preset screen | 1,200dpi | 600dpi | |

|---|---|---|---|

| Photo mode | Smooth gradations even for low-resolution photos | 120lpi | 86lpi |

| Text/Photo mode | Optimal setting for both text and photos | 170lpi | 106lpi |

| Text mode | Even small text are clearly printed for easy legibility | 212lpi | 141lpi |

Front and back printing position adjustments

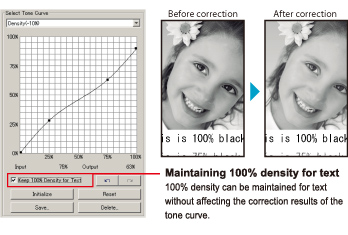

Tone curve utility

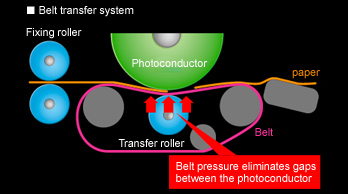

Belt transfer system

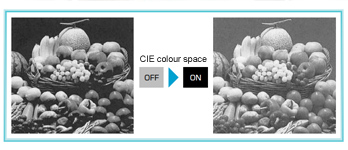

CIE colour space

* Output speed will be 10-20% slower.

Simitri HD toner

Improve efficiency with advanced operations

Improve workflow efficiency with job management

• Streamline complex output operations with lexible worklow management.

– Job list display

– Job ticket editing

– Job schedule management

• Common user interface with bizhub PRESS/PRO colour devices

• Large 15-inch touch panel screen

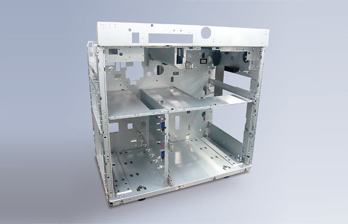

Highly rigid frame and highly durable parts

High affinity with bizhub office devices

Main unit authentication and IC card authentication*

* Optional

Use of recycled materials

Centralised management and TCO reduction