We want to…

Ensure excellence in Black and White printing.

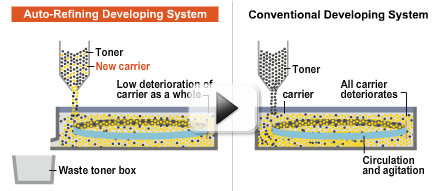

New Auto-Refining Developing System

With the new bizhub’s Auto-Refining Developing System, carrier in the black developing unit is premixed in the toner cartridge and supplied as toner is consumed. Deteriorated carrier is expelled with the toner, reducing overall deterioration in the developing unit. This process helps to maintain stable black & white image quality over the long term. This feature is particularly relevant in offices that have high-volume black & white output.

Reduce power use and warm-up time.

IH Fixing

Induction Heating (IH) Fixing technology only heats the roller’s surface, rather than the entire roller. This reduces power consumption during the fixing process and results in shorter warm-up times. In addition, this feature automatically reduces residual fixing heat when no print jobs are taking place, further contributing to energy savings.

Induction Heating (IH) Fixing technology only heats the roller’s surface, rather than the entire roller. This reduces power consumption during the fixing process and results in shorter warm-up times. In addition, this feature automatically reduces residual fixing heat when no print jobs are taking place, further contributing to energy savings.

Set up operation to meet office needs.

Three Image Stabilisation Modes

We’ve optimised image stabilisation control by providing three separate modes tailored to your office’s printing needs. Standard Mode is perfect when overall print volume is low and colour usage is moderate. BW Priority Mode is the best for those offices that mostly utilize black & white printing. Finally, Colour Priority Mode is the alternative that offers the most image stabilisation efficiency for high volume, colour output needs.

Output quality documents on various papers.

Simitri HD Toner

The small size and consistent shape of Simitri HD toner particles ensure sharp reproduction of text as well as line drawings. Its smooth outer surface provides excellent hold and promises high image quality across a diverse media mix. Furthermore, the new bizhub uses low-temperature fixing to affix the Simitri HD toner. Using less heat saves energy and effectively reduces paper stress.

Combine high speed and high image quality.

4-colour, Twin-Beam Laser Unit

To create a smaller footprint within the office while providing greatly reduced energy consumption for a colour machine, the new bizhub uses just one laser unit for all four toner drums. A single polygon motor is employed to cover all four colours, and a system of precisely positioned mirrors directs the beams for each of them. To prevent mismatching of colour layers due to drum unevenness, a precision array of correction lenses align them exactly with the black toner drum.

Offer superior actual productivity.

Boost PPH: B&W 99%, Colour 98%

All MFPs must pause operation periodically to perform image stabilisation to ensure consistent image quality. Actual productivity, therefore, has to exclude the time required for self-maintenance. By separating the timing for cleaning, alignment correction and stabilisation, the new bizhub is able to intelligently select when to perform these functions, thereby minimising the affect of downtime on productivity. Furthermore, by shortening the amount of time required for each function, total productivity per hour is even better.

Eliminate striping in scans.

Noise and Dust Reduction ADF

The self-cleaning function on the document feeder, assisted by the anti-dust coating on the platen glass, automatically clears away dust and paper residue to reduce streaks and other noise in scan data.

Deliver swift output from a compact body.

3-sheet Paper Feed Path

The new bizhub uses an optimized paper path that moves three sheets of paper at once, for high-speed output and 100% duplexing productivity.Also, all four colours are printed in a single pass rather than one at a time, for more reliable four-colourprinting at B&W speeds.

Provide stable paper feeding operation.

3-Speed Loop Control

Three-speed loop control stabilises paper transport, while the vertical design provides greater stability and compactness. Speed differences that occur between the transport and fixing rollers are corrected by stabilising the paper flow while monitoring the size and shape of the loop that forms before the fixing roller. The 3-speed control system allows finer adjustment than conventional 2-speed systems, for optimised feed speed.

Three-speed loop control stabilises paper transport, while the vertical design provides greater stability and compactness. Speed differences that occur between the transport and fixing rollers are corrected by stabilising the paper flow while monitoring the size and shape of the loop that forms before the fixing roller. The 3-speed control system allows finer adjustment than conventional 2-speed systems, for optimised feed speed.

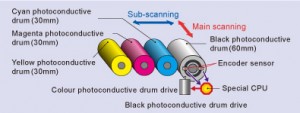

Enlarge the black toner drum for greater durability.

Colour Gap Prevention

To increase the life of the black toner drum while still making the main unit compact, the colour drums are smaller. Because of this, the new bizhub uses two separate driver CPUs to control drum rotation and prevent speed differences that can result in gaps between colours.

New Brush-type Paper Dust Cleaning Mechanism Employed in Front Scanning Unit

New paper dust cleaning mechanism employs a brush to clean the scanner slit glass. Previous models cleaned the glass by gathering paper dust along the edge of a scraper and using the trailing edge of the original to sweep it out. Differences in paper type would result in uneven cleaning pressure. The C652DS uses a cleaning brush with a large contact surface to ensure better removal of paper dust, which can cause striped copies/scanned images if it accumulates on the slit glass. This improvement provides reliable scanning quality that is not dependent on paper path conditions or paper type.